As industrial automation pushes into smaller, smarter, and more distributed applications, the demand for compact yet precise position sensing continues to soar. Housed resolvers—electromagnetic devices that provide absolute angular feedback—are evolving to meet these challenges.

1. The Miniaturization Trend in Industrial Equipment

1.1 Why Smaller Matters in Today's Automation

Over the past decade, industries from robotics to medical devices have steadily gravitated toward smaller, lighter, and more power-efficient equipment. Two key factors drive this miniaturization trend:

Space Constraints

In collaborative robots (cobots) working alongside humans, every gram and millimeter counts. Smaller joints and end-effectors allow for more dexterous motion in confined workspaces.

Energy Efficiency

Reducing mass lowers inertial loads, cutting power consumption and heat generation. In battery-powered systems like drones or portable diagnostic tools, compactness directly translates into longer runtime.

1.2 High-Growth Sectors: Cobots, Drones, Medical Devices

Collaborative Robots (Cobots)

Cobots are increasingly common on factory floors, performing tasks such as assembly, pick-and-place, and quality inspection. Smaller joint modules need equally small position sensors to maintain the overall compact footprint of the arm.

Unmanned Aerial Vehicles (Drones)

For drones—industrial inspection, mapping, or even delivery—payload weight is at a premium. Miniature resolvers enable precise motor control without sacrificing lift capacity.

Medical and Diagnostic Devices

Instruments such as surgical robots, endoscopic tools, and handheld scanners demand absolute precision in sub-millimeter cavities. Miniaturized housed resolvers can deliver that exact feedback in harsh sterilization environments.

Across all these sectors, the integration of smaller sensors does more than save space: it unlocks new capabilities in agility, efficiency, and form factor that larger devices simply cannot match.

2. Precision and Structural Challenges of Micro Resolver Design

Shrinking a housed resolver to just a few centimeters—or even millimeters—poses two fundamental engineering challenges:

2.1 High Resolution in a Tiny Package

Angular resolution in a resolver depends on the number of windings (poles) in the stator and rotor, as well as the precision of the electromagnetic coupling. As dimensions shrink:

Winding Density Increases

Fewer turns per coil, closer wire spacing, and tighter tolerances are required to keep signal amplitudes strong and sinusoidal.

Pole Geometry Becomes Critical

Microscopic variations in pole shape or magnet placement, even a few microns off, can introduce waveform distortion—translating into poor angle accuracy or higher jitter.

Meeting target resolutions of ±8 arcminutes or better in a package under 20 mm diameter demands ultra-high-precision machining, advanced winding techniques, and rigorous quality control.

2.2 Mechanical and Thermal Stability

Miniature resolvers face amplified mechanical stresses:

Vibration and Shock

Small mass means less inherent damping; even minor external shocks can shift internal components or degrade bearing interfaces.

Thermal Expansion

In tiny assemblies, differential expansion between housing, magnet, and winding materials can cause misalignment or change air-gap dimensions, impacting signal integrity.

To overcome these issues, designers must select materials with matched coefficients of thermal expansion, implement reinforced micro-bearings, and optimize housing rigidity—all while keeping overall weight minimal.

3. Materials and Process Innovations Driving Micro Resolver Development

Recent advances in both materials science and manufacturing processes have opened the door to reliable micro housed resolvers. Three areas stand out:

3.1 High-Precision Winding

Traditional resolver coils are hand-wound or machine-wound on relatively large bobbins. For micro resolvers:

Automated Micro-Winding Machines

These can place ultra-fine enamelled copper wires (diameters ≤ 50 µm) with micron-level positioning accuracy.

Epoxy Encapsulation

After winding, coils are impregnated with low-stress epoxy to stabilize turns against vibration and thermal cycling.

This approach ensures consistent coil inductance and minimizes turn-to-turn capacitance variations that could distort the sine/cosine outputs.

3.2 Micro-Magnet Fabrication

The rotor's magnetic poles often use rare-earth magnets (e.g., NdFeB) to generate the excitation field. In micro resolvers:

Micro-Segmented Magnet Arrays

Instead of a single ring magnet, tiny segmented magnets are precisely placed and bonded onto the rotor.

Laser-Cut Magnetic Shapes

Laser trimming ensures each segment matches design tolerances within a few microns, preserving field uniformity.

These innovations maintain strong, uniform magnetic excitation even in extremely compact rotors.

3.3 Additive Manufacturing for Housings

Conventional housings are machined from aluminum or stainless steel—costly and limited in geometric complexity at small scales. Today:

Metal 3D Printing (Laser Powder Bed Fusion)

Enables one-piece, complex housing geometries with internal mounting features and integrated cooling channels—all in a single build.

Polymer 3D Printing for Prototyping

High-temperature polymers can be used to prototype and test mechanical fit before committing to metal production.

Additive manufacturing reduces lead times, minimizes material waste, and allows rapid iteration of new micro resolver designs.

4. Windouble's Micro Resolver R&D Direction

Shanghai Yingshuang (Windouble) has embedded these cutting-edge techniques into its dedicated micro resolver development program. Key highlights include:

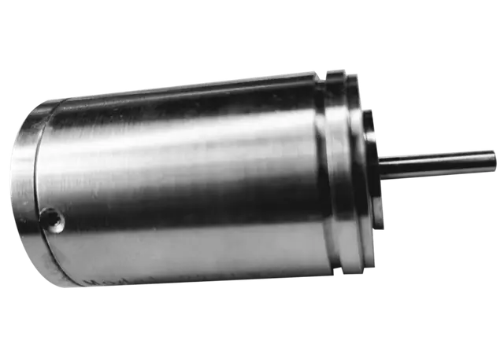

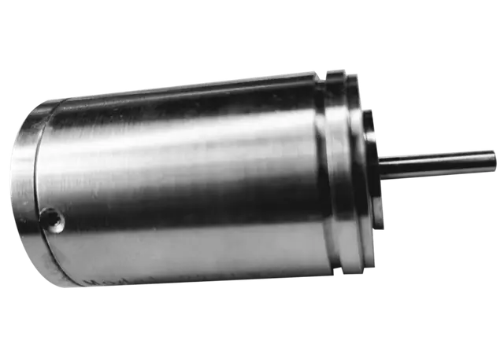

4.1 Current Smallest-Footprint Model

Despite its miniature size, the WDR-M10 delivers absolute position feedback, brushless operation, and superior EMI immunity—matching performance metrics of resolvers twice its size.

4.2 Customization and Modular Design

Windouble offers modular rotor assemblies and interchangeable stator inserts, allowing customers to tailor:

Pole Counts: from 2 to 16 poles

Connector Types: micro-D, pico-blade, or solder-pad

Housing Materials: lightweight aluminum or PEEK polymer for medical/clean-room applications

This flexibility accelerates integration into custom applications, from surgical robots to smart prosthetics.

4.3 Automated Testing and Calibration

Given the tight tolerances, Windouble invests heavily in:

Automated Optical and Electrical Inspection

3D microscopes verify pole geometry; high-precision bridge measurement captures winding resistance and inductance.

AI-Assisted Calibration

Machine-learning algorithms analyze signal waveforms to detect subtle distortions, automatically applying digital compensation coefficients in the resolver-to-digital converter (RDC).

These processes ensure every micro resolver meets spec before shipment, reducing field failures.

5. Future Applications for Micro Housed Resolvers

The convergence of miniaturization, materials innovation, and system-level intelligence unlocks exciting new applications:

5.1 Precision Instruments and Metrology

Devices such as coordinate measuring machines (CMMs), optical scanners, and precision turntables benefit from sub-0.01° feedback in a tiny form factor—enabling portable or handheld metrology tools.

5.2 Avionics and Space Systems

Weight saving is paramount in drones, satellites, and small spacecraft. Mini resolvers can replace bulkier encoders in gimbals, solar panel trackers, and antenna positioning modules, contributing to lower launch costs and longer mission lifespans.

5.3 Micro Servo and Actuator Systems

From camera gimbals in filmmaking drones to nanopositioning stages in semiconductor lithography, micro resolvers provide the absolute feedback necessary for closed-loop control in devices where every micron of motion counts.

5.4 Wearable and Medical Robotics

Emerging exoskeletons, haptic gloves, and surgical manipulators require discreet, lightweight sensors embedded close to joints. Micro housed resolvers embedded within linkages can deliver reliable, sterilizable feedback in these sensitive environments.

Conclusion

The future of housed resolvers lies in their ability to shrink without compromise—delivering absolute, brushless position feedback in packages small enough for next-generation robotics, aerospace, and medical devices. Through advancements in micro-winding, magnet fabrication, and additive manufacturing, companies like Windouble are pushing the boundaries of what's possible:

Compact Designs under 10 mm diameter

High Accuracy within ±10 arcminutes

Rigorous Qualification via AI-driven calibration

Modular Flexibility for diverse connector and pole-count options

As automation systems continue to demand more precision, efficiency, and integration in tighter spaces, micro housed resolvers will become indispensable components—from collaborative robots navigating factory floors to satellites adjusting solar arrays in orbit.

By choosing a partner with deep expertise in both traditional resolver technologies and cutting-edge microfabrication—like Shanghai Yingshuang (Windouble) Electric Machinery Technology Co., Ltd.—engineers can confidently design the next wave of industrial equipment and smart devices.

Discover Windouble's Micro Housed Resolvers:

Visit www.windoublesensor.com to download datasheets, request samples, or discuss custom micro resolver solutions tailored to your application.