In an era where industrial processes demand ever-higher levels of precision, reliability, and uptime, the choice of position feedback device can make or break system performance. Housed resolvers have steadily gained favor among engineers and integrators alike for their unique combination of robustness and accuracy.

Company Introduction and Product Background

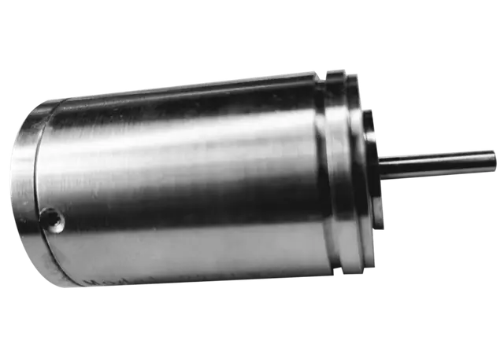

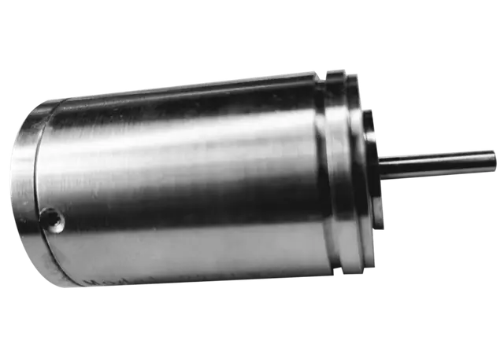

Shanghai Yingshuang (Windouble) Electric Machinery Technology Co., Ltd. is a leading manufacturer specializing in rotary position sensors. With over a decade of experience in sensor design, precision machining, and quality control, Windouble has established itself as a trusted partner for OEMs and system integrators worldwide. Their product lineup spans from incremental and absolute encoders to geared encoders and, importantly, housed resolvers—electromechanical devices that deliver absolute angular position feedback in the harshest operating environments.

Windouble's commitment to research and development has driven continuous improvements in resolver winding techniques, housing materials, and integrated testing. By combining in-house design capabilities with strict ISO 9001 production standards, they ensure each resolver meets precise electrical and mechanical tolerances. The result is a family of housed resolvers renowned for long life, minimal maintenance, and consistent performance under challenging conditions.

The Role of Housed Resolvers in Industrial Automation

At its core, a resolver is an electromagnetic rotary transformer that converts shaft angle into analog sine and cosine signals. Unlike optical encoders, which rely on a light source and sensor to detect marks on a disk, resolvers operate via inductive coupling—making them inherently more resistant to dust, oil, and vibration.

Housed resolvers take this ruggedness a step further by enclosing the stator, rotor, and windings within a sealed outer casing. This “housed” design creates a robust barrier against external contaminants and mechanical shock. In industrial automation, where equipment must run continuously in environments laden with metal shavings, hydraulic fluids, or extreme temperatures, housed resolvers provide absolute position feedback without sacrificing accuracy.

Structural Integrity and Environmental Adaptability

Fully Enclosed Design Advantages

Dust and Moisture Protection

The sealed housing prevents ingress of particulates and fluids. With protection ratings typically at IP65 or above, housed resolvers can withstand direct water jets and heavy dust concentrations. This makes them ideal for applications in metalworking, food processing, or outdoor machinery.

Mechanical Shock and Vibration Resistance

The rigid enclosure—often machined from aluminum alloy—guards the internal windings and rotor assembly against shock and vibration. Windouble's housings are tested to endure up to 25 g of shock and 20 g RMS vibration, ensuring stable operation even on high-speed rotating equipment or mobile platforms.

Temperature Range Handling

Standard Windouble housed resolvers operate reliably from –40 °C to +100 °C, with custom versions extending up to +150 °C.High-temperature insulation materials and epoxy-sealed windings prevent degradation of signal quality when ambient conditions exceed those tolerable by optical devices.

Precision Angular Position Detection

Brushless Structure for Stable Signals

Housed resolvers are contactless devices—there are no brushes, wiper contacts, or sliding elements inside. The absence of mechanical contacts means:

Zero wear on sensing surfaces, preserving long-term accuracy

Elimination of electrical noise from arcing or brush chatter

Consistent torque characteristics, avoiding friction-induced signal drift

This brushless design results in a stable analog output of sine and cosine voltages proportional to the shaft angle, enabling controllers to interpolate position at resolutions down to a few arcminutes.

Immunity to Electrical Interference

In many industrial settings, powerful inverters, high-current busbars, and welding machines generate substantial electromagnetic interference (EMI). Resolvers, being transformer-based, inherently reject common-mode noise. When paired with modern resolver-to-digital converters (RDCs) that feature EMI-hardened front ends, housed resolvers deliver clean, accurate position data where optical encoders might falter.

Comparison with Optical Encoders

Feature | Housed Resolver | Optical Encoder |

Contaminant Resistance | Operates in dust, oil, and moisture | Requires clean environment |

Temperature Tolerance | –40 °C to +100 °C (–150 °C optional) | Typically –20 °C to +70 °C |

Mechanical Wear | None (contactless) | Disc and readhead wear over time |

EMI Immunity | High (transformer operation) | Low to moderate |

Absolute Position on Startup | Yes (no homing needed) | Often no (requires index pulse) |

Extended Service Life and Reduced Maintenance Costs

Reduced Mechanical Wear

Because resolvers lack sliding or rotating contacts, they avoid the mechanical wear that plagues encoders and potentiometers. This translates directly into:

For high-cycle machinery—such as pick-and-place robots running hundreds of thousands of moves daily—this longevity dramatically lowers the risk of unplanned downtime.

Low or No Maintenance

No Cleaning Required: Sealed enclosures keep contaminants out, so there's no routine cleaning of optical surfaces.

No Calibration Needed: Absolute feedback means resolvers always know their position after power loss, negating homing routines and calibration checks.

Cost Savings Over Lifetime: When factoring in labor, spare parts, and lost production time, the lifecycle cost of a housed resolver can be 30–50% lower than that of an optical encoder in harsh environments.

Application Domains and Case Summaries

Factory Automation

In automated production lines—such as assembly, packaging, or material handling—consistent motion control is paramount. Housed resolvers enable precise torque control and smooth velocity profiling in servo motors, ensuring parts are placed or welded accurately every cycle.

Case in Point: A major beverage bottling plant integrated Windouble housed resolvers into its labeling robots. Despite high humidity and splashes from washdowns, the resolvers maintained sub-0.1° accuracy for over two years without any sensor-related downtime.

Servo Systems

Servo drives rely on fast, accurate feedback to maintain position under dynamic loads. Housed resolvers provide the analog signals needed by high-speed RDC modules, offering millisecond-level response times.

Case in Point: An aerospace component manufacturer retrofitted legacy CNC servo axes with Windouble housed resolvers. The upgrade eliminated encoder failures due to coolant contamination and allowed tighter dimensional tolerances on turbine blade machining.

Robotic Joint Applications

Robotic joints experience complex motion profiles, frequent acceleration, and variable loads. The resilience of housed resolvers makes them especially suited for feedback in multi-axis robots used in welding, painting, or pick-and-place.

Case in Point: A major automotive OEM replaced optical encoders on robotic spot-welding arms with Windouble housed resolvers. Not only did system reliability improve, but the maintenance interval extended from quarterly to annually—delivering significant cost savings.

Conclusion

Housed resolvers represent a critical advancement in motion feedback technology, marrying the precision of rotary position sensing with industrial-grade durability. Shanghai Yingshuang (Windouble) Electric Machinery Technology Co., Ltd.'s housed resolvers stand out through:

Robust Enclosed Design: Full protection against dust, moisture, vibration, and shock.

Stable, Brushless Operation: Zero wear, low electrical noise, and consistent analog output.

High EMI Immunity: Reliable feedback even in electrically noisy environments.

Extended Lifespan: Tens of millions of cycles without performance degradation.

Minimal Maintenance: No cleaning, calibration, or realignment needed over long service intervals.

From factory automation and servo control to robotic joints and aerospace applications, housed resolvers deliver the accuracy and uptime that modern industry demands. By choosing Windouble's family of housed resolvers, engineers and system designers can minimize lifecycle costs, reduce unplanned downtime, and achieve precise motion control—even under the harshest operating conditions.

Ready to enhance your automation system's reliability?

Visit www.windoublesensor.com to explore Windouble's complete range of housed resolvers, download datasheets, or request a tailored quotation today.