With the rapid development of electric vehicles (EVs), optimizing motor efficiency has become a crucial factor in extending driving range, reducing energy consumption, and improving overall vehicle performance. One of the critical components that contribute to this optimization is the variable reluctance resolver (VR resolver). This sensor plays a fundamental role in accurately detecting the rotor position, enabling precise motor control and efficiency improvements.

In this article, we will explore the purpose of the VR resolver in EV drive motors, how it enhances electric motor efficiency, key factors to consider when selecting a suitable motor resolver, and other essential aspects. Understanding the significance of variable reluctance resolvers in modern EV systems can help engineers and manufacturers make informed decisions for optimizing performance and efficiency.

What is the Purpose of the Resolver in the EV Drive Motor?

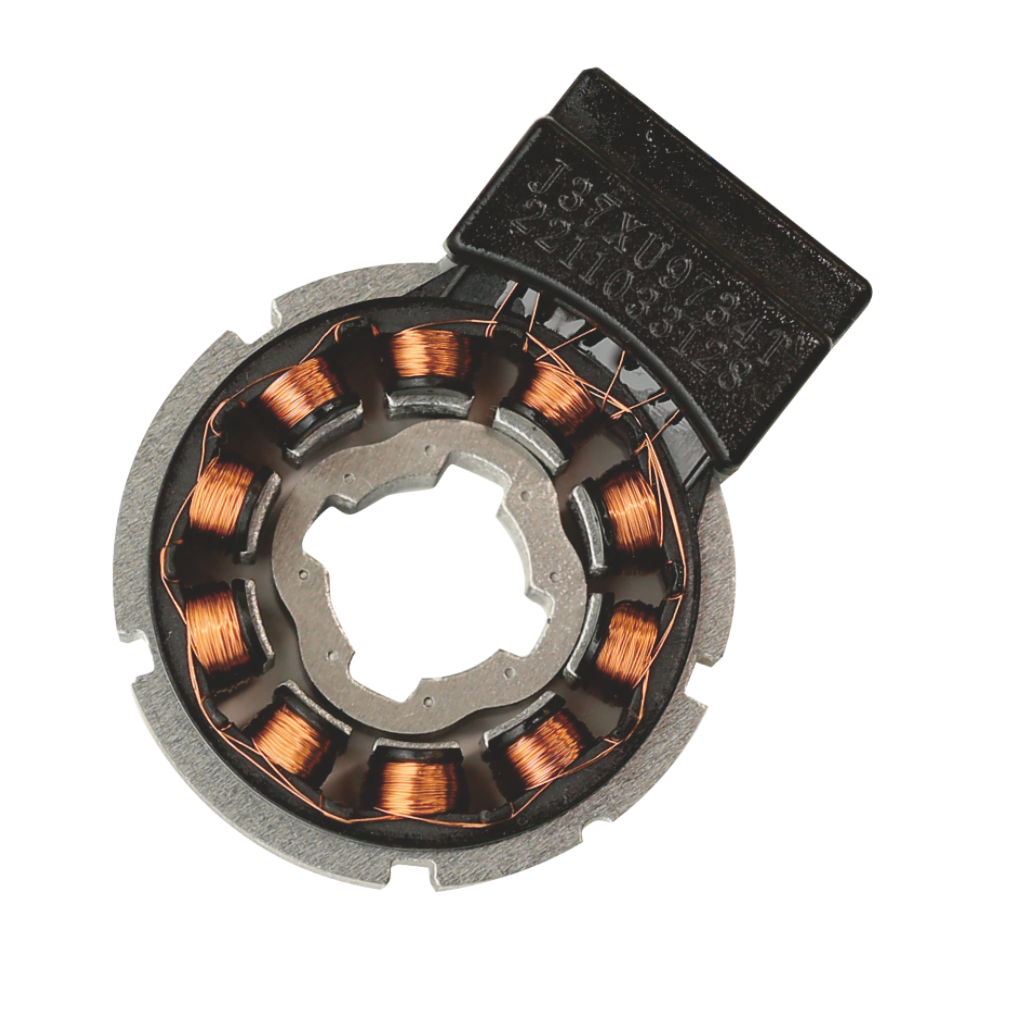

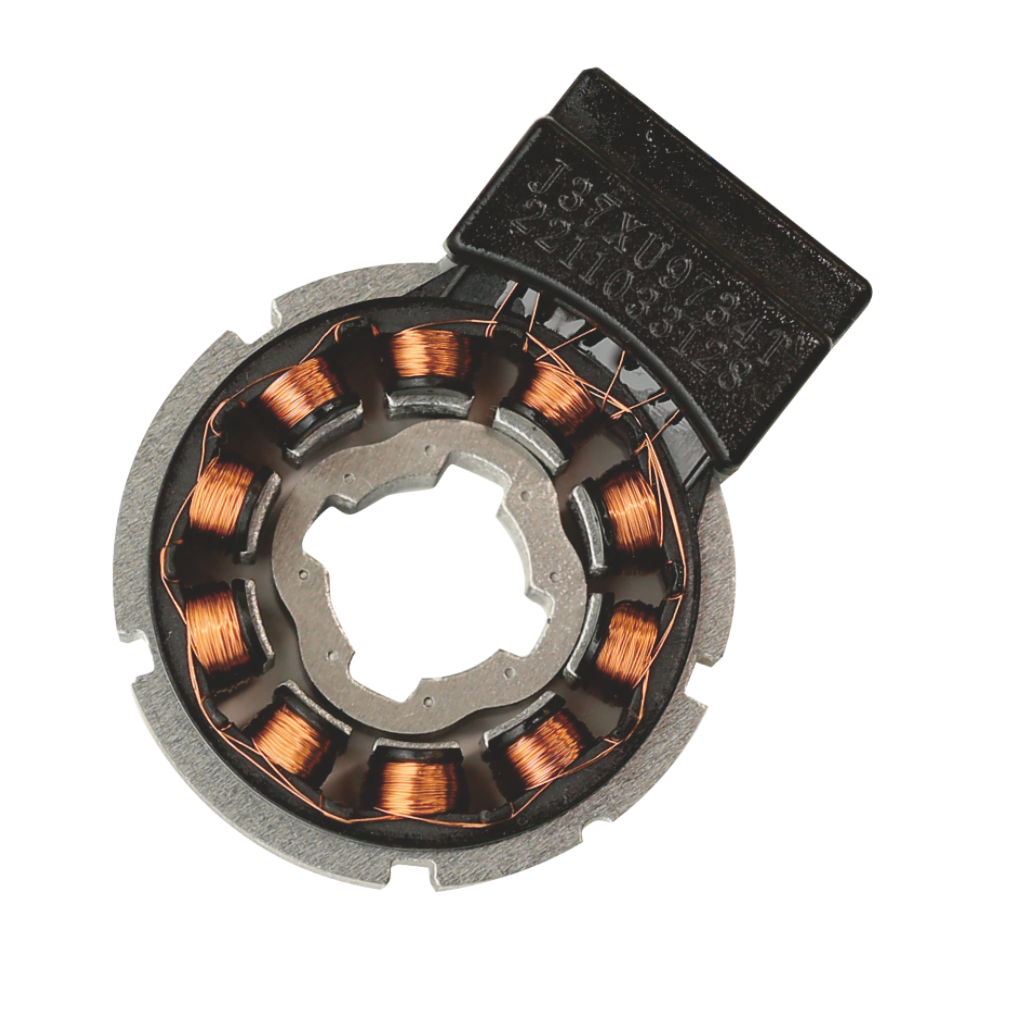

A resolver is an electromechanical sensor used to determine the position of a rotating shaft, commonly found in electric motors, including those used in EVs. The VR resolver is a specific type of resolver that operates based on changes in magnetic reluctance. It is widely used in automotive applications due to its robustness, high accuracy, and reliability under extreme conditions.

Key Functions of a Resolver in EV Motors

Rotor Position Detection

The primary function of a VR resolver is to provide real-time feedback on the rotor's position. This information is essential for the precise control of the motor's operation, ensuring smooth torque delivery and optimized energy efficiency.

Speed Sensing

Apart from position detection, variable reluctance resolvers also provide speed feedback. This data is crucial for maintaining stable motor operation and adjusting power output based on driving conditions.

Facilitating Field-Oriented Control (FOC)

Modern electric motors in EVs utilize field-oriented control (FOC), which relies on rotor position data. The VR resolver ensures that the motor controller can accurately determine the magnetic field orientation, leading to improved torque control and reduced energy losses.

Enhancing Motor Reliability

Unlike some other position sensors, VR resolvers are robust against harsh environmental factors such as extreme temperatures, vibrations, and electromagnetic interference. This resilience makes them ideal for automotive applications where reliability is paramount.

How Does VR Resolver Contribute to Electric Motor Efficiency?

The efficiency of an electric motor is directly influenced by the accuracy and reliability of the rotor position detection system. The variable reluctance resolver plays a critical role in optimizing motor performance by ensuring precise control over motor functions. Here's how it contributes to electric motor efficiency:

1. High Accuracy in Rotor Position Detection

The VR resolver provides highly accurate rotor position data, which allows the motor controller to optimize power delivery. This ensures that the motor operates at its peak efficiency, reducing energy losses and improving overall performance.

2. Reduction of Energy Losses

Motor efficiency is significantly affected by energy losses due to inaccurate position sensing. Traditional encoders and Hall effect sensors may introduce errors, leading to increased power consumption. Variable reluctance resolvers, on the other hand, have minimal error margins, preventing unnecessary power wastage and improving efficiency.

3. Optimized Torque Control

In electric motors, precise torque control is essential for smooth acceleration and deceleration. The VR resolver ensures that the motor controller receives real-time and accurate rotor position data, facilitating optimal torque management. This results in reduced energy consumption and enhanced driving experience.

4. Robust Performance Under Extreme Conditions

The variable reluctance resolver is highly resistant to temperature variations, electromagnetic interference, and mechanical vibrations. Unlike optical encoders, which may fail in harsh environments, VR resolvers maintain accurate performance, ensuring consistent motor efficiency over time.

5. Supports High-Speed Motor Operation

Many modern EV motors operate at high speeds, requiring precise position sensing to maintain efficiency. The VR resolver is capable of accurately detecting rotor position even at high RPMs, making it a preferred choice for high-performance EV motors.

6. Integration with Advanced Motor Control Systems

Modern EVs rely on sophisticated motor control algorithms, such as vector control and field-oriented control (FOC), to maximize efficiency. The variable reluctance resolver seamlessly integrates with these systems, providing real-time feedback that enhances motor control precision and reduces energy losses.

How to Select the Suitable Motor Resolver?

Choosing the right resolver for an EV drive motor is crucial for maximizing efficiency, reliability, and performance. Here are some key factors to consider when selecting a VR resolver:

1. Accuracy and Resolution

High accuracy ensures precise rotor position detection, leading to improved motor control.

Resolution should be sufficient to meet the motor's operational requirements, typically in the range of 10-16 bits for high-performance applications.

2. Operating Speed Range

The VR resolver should support the full speed range of the motor, ensuring accurate position feedback even at high RPMs.

Look for resolvers with a wide frequency response to accommodate varying operating conditions.

3. Environmental Resistance

Variable reluctance resolvers should be capable of withstanding extreme temperatures, vibrations, and electromagnetic interference.

Automotive-grade resolvers are designed to operate in harsh conditions, making them ideal for EV applications.

4. Compatibility with Motor Controllers

Ensure that the VR resolver is compatible with the motor controller's interface and supports the required signal processing algorithms.

Some controllers may require additional signal conditioning, so compatibility should be verified before selection.

5. Durability and Longevity

Since EV motors operate under demanding conditions, the VR resolver should have a long lifespan with minimal maintenance requirements.

Look for products with a proven track record of reliability in automotive applications.

6. Cost vs. Performance Trade-off

While high-end variable reluctance resolvers offer superior accuracy and durability, they may come at a higher cost.

Consider the trade-off between performance and budget constraints when selecting the most suitable resolver.

Comparison Table: Optical Encoder vs. VR Resolver

| Feature | Optical Encoder | VR Resolver |

| Accuracy | High | High |

| Environmental Resistance | Low | High |

| Cost | Expensive | More Affordable |

| Operating Speed Range | Moderate | Broad Range |

| Durability | Moderate | High |

| Suitability for EV Motors | Limited | Excellent |

Conclusion

The variable reluctance resolver plays a crucial role in optimizing electric motor efficiency by providing accurate rotor position feedback, minimizing energy losses, and enhancing torque control. Compared to other position sensors, VR resolvers offer superior reliability, durability, and performance under extreme conditions, making them an ideal choice for EV applications.

Selecting the right VR resolver involves considering factors such as accuracy, speed range, environmental resistance, and compatibility with motor controllers. By choosing a high-quality resolver, EV manufacturers can improve vehicle efficiency, extend battery life, and enhance overall driving performance.

FAQs

1. What is a variable reluctance resolver?

A variable reluctance resolver (VR resolver) is a position sensor that detects the rotor position of an electric motor based on changes in magnetic reluctance. It is widely used in EV motors for its high accuracy and reliability.

2. How does a VR resolver improve motor efficiency?

The VR resolver provides precise rotor position feedback, allowing the motor controller to optimize power delivery, reduce energy losses, and improve torque control, leading to higher efficiency.

3. What are the advantages of using a VR resolver in an EV motor?

High accuracy in rotor position detection

Robust performance in extreme conditions

Improved torque control and energy efficiency

Long lifespan with minimal maintenance

4. How does a VR resolver compare to an optical encoder?

While optical encoders offer high accuracy, they are less durable in harsh environments. The VR resolver provides comparable accuracy with superior robustness, making it a better choice for automotive applications.

5. What factors should be considered when selecting a VR resolver?

Key factors include accuracy, operating speed range, environmental resistance, durability, compatibility with motor controllers, and cost-effectiveness.